How is a CNC gantry milling machine processed?

The milling of gantry machining centers is mostly completed using the reverse milling method. However, it is advisable to use forward milling as much as possible to achieve better processing results. When milling with a gantry milling machine, the milling width should be approximately 2/3 of the milling cutter diameter, which ensures that the blade can immediately cut into the workpiece from the beginning, with almost no resistance. If it is less than 1/2 of the milling cutter diameter, the blade will start to collide with the workpiece again, because the cutting thickness decreases during cutting, and the feed rate per tooth will also decrease due to the narrowing of the radial cutting width. The conflicting results shorten the tool life, and for hard alloy tools, increasing the feed rate per tooth and reducing the cutting depth are more advantageous. So during rough milling, if the radial cutting width is smaller than the milling cutter radius, increasing the cutting amount will improve the tool life and shorten the processing time of the gantry milling machine. Of course, precision milling requires a smooth surface of the workpiece, so the cutting amount should be limited.

What is the difference between a gantry milling machine and a lathe?

1. A lathe is a machine tool that primarily uses turning tools to turn rotating workpieces. On the lathe, drills, reamers, taps, dies, and knurling tools can also be used for corresponding processing. Lathes are primarily used for machining shafts, discs, sleeves, and other workpieces with rotating surfaces.

2. Rotating processing machinery such as milling and drilling machines are all extended from lathes. A milling machine is a machine tool that uses a milling cutter to process workpieces. Generally, the rotation motion of the milling cutter is the main motion, while the movement of the workpiece and milling cutter is the feed motion. In addition to milling flat surfaces, grooves, gear teeth, threads, and spline shafts, milling machines can also process more complex profiles with higher power than planers, and are widely used in mechanical manufacturing and repair departments. In addition, it can also be used for machining the surface and inner holes of rotating bodies, as well as for cutting work.

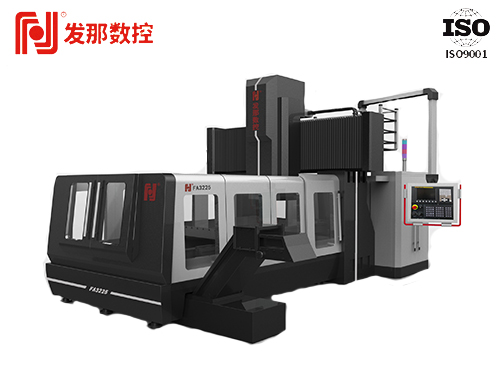

Overall, gantry milling machines have the characteristics of rigidity, high power, easy operation, simple structure, and comprehensive functionality, which are widely used in the mechanical manufacturing industry.