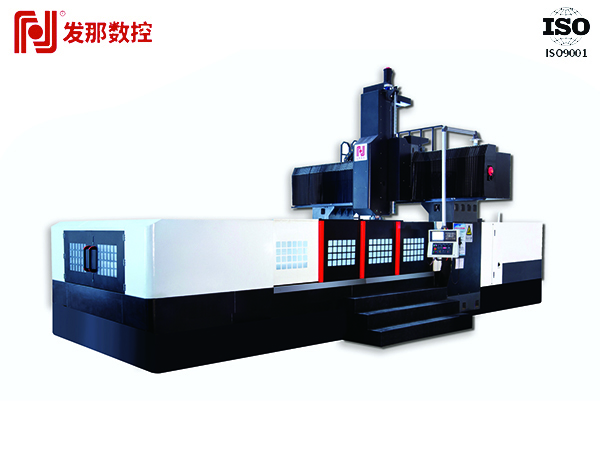

Safety measures to be adopted for CNC gantry milling machine processing

CNC gantry milling machine workers divide the motion coordinates of the cutting tool and the workpiece into smaller units, that is, smaller displacements. According to the requirements of the workpiece program, the CNC system moves each coordinate by several small displacements, and then completes the relative motion between the tool and the workpiece to complete the machining of the workpiece.Due to the wide application of CNC gantry milling machine in the processing industry, the grinding machine operates at a fast speed and has a high grinding force. Therefore, in our daily operation and use, we should adopt safe protective measures to not only prevent the danger of crushing the grinding wheel, but also prevent the inhalation of a large amount of workpiece debris from grinding. When starting up and running, check the grinding machine to ensure the tightness of the workpiece and prevent it from derailing, flying out and injuring people or crushing the grinding wheel during the grinding process.

CNC gantry milling machines are mainly used for machining workpieces with disorderly shapes, but the structure of the fixtures used is often not messy. The selection of fixtures can be confirmed based on the batch size of the production workpiece. For single piece, small batch, and heavy workload mold processing, it is generally possible to directly adjust the final positioning and clamping on the machine tool workbench, and then confirm the position of the workpiece through the setting of the machining coordinate system.

Safety measures to be adopted for CNC gantry milling machine processing

22

Oct